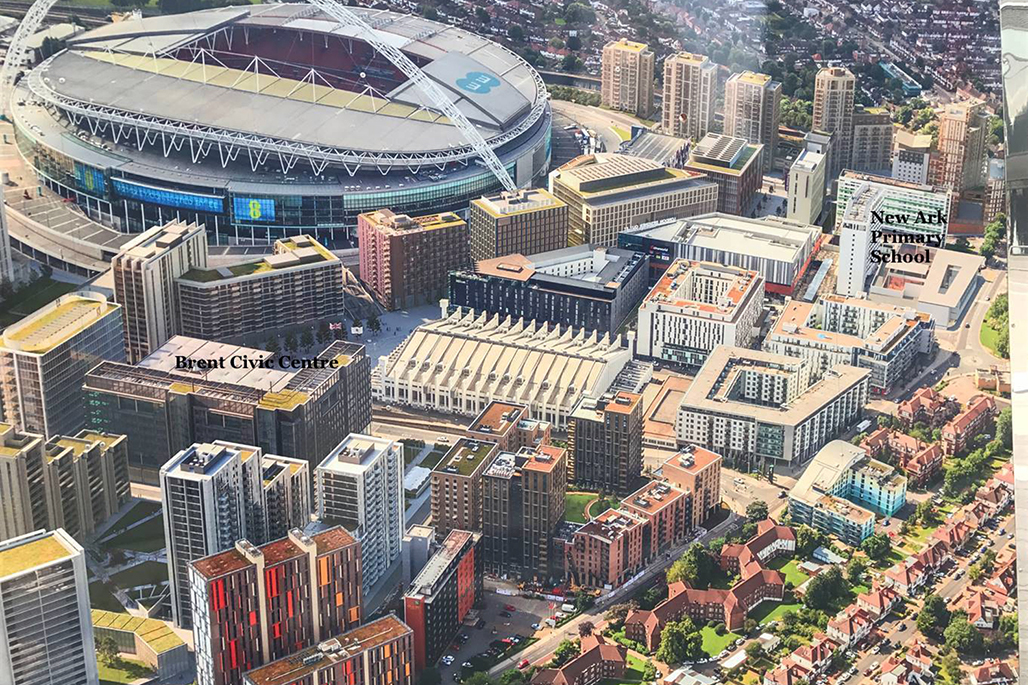

Wembley Park - NW09 & NW10

About this project

A new development bringing over 8,000 new homes and a 7-acre park space, located in North-West London. Wembley Park’s eighty-five-acre mixed-use regeneration development by Quintain promotes a sustainable way of living and commuting, as well as it is a thriving business community.

Cilantro Engineering are responsible for the design and installation of the entire MEP Package to the Repton Gardens Project, including all Life Safety Systems. We are delighted to play a part in the regeneration of this development, working with Blue Chip Clients’ McLaren and Quintain. This element of the scheme consists of delivering services to 396 build-to-rent homes for plots NW09 and NW10 and Repton House, spread across three residential blocks. This includes the installations of Hotel Style Risers which incorporate prefabricated pipework risers, the central direct heating network to supply LTHW, DHW along with BCWS, Sprinkler (residential and commercial) and Ducting Exhaust to each apartment via a central MEV System in NW09 and 10. We will also install an extension to the site wide District Heating Network to extend the EON managed network, Emergency Lighting and Internal Wall Mock-up.

Our installations will provide Shell and Core services to 8 Retail units, residents’ parking, amenity link consisting of work from home space and 1,200 square metres earmarked for a medical centre, GP surgery and children’s play area. As part of the tenant agreement, each apartment is connected to the entire site wide Wi-fi system allowing individual access securely. Cilantro Engineering are proud to be working as part of this impressive project, continuing to transform Wembley Park and its community with McLaren.

For more information about this project visit the main contractor’s website.

Share this project via social media or email:

Our accreditations

Health & Safety

At Cilantro Engineering, we pride ourselves on upholding the highest Health and Safety standards across all our projects. We assemble our highly skilled workforce to manage Health and Safety Risk in a holistic manner.

Our Health and Safety department carry out extensive monitoring, auditing and training to ensure our site teams are compliant with up-to-date Health and Safety regulations and industry best practice measures. Health and Safety is driven throughout our business by our Senior Management team. They are supported by dedicated professionals to assist them in delivering excellence across all disciplines and levels across Cilantro Engineering projects.

Electrical and Mechanical Safe Systems of Work

Electrical and Mechanical Safety is a primary focus on all our projects. With high-risk activities taking place, Electrical and Mechanical Safe Systems of Work are paramount.

We take pride in our Electrical and Mechanical Safe Systems of Work, comprising of:

- A designated Company Duty Holder, overseeing Electrical and Mechanical safety of all projects

- Project specific Authorised Persons

- Comprehensive Safety Measures to mitigate risks

- Competent Electrical Test Engineers to commission systems

- Pro-actively educating Clients and Stakeholders

Our continued registration with the UK leading NICEIC accreditation body makes Cilantro Engineering one of the leading MEP providers.

We all have an individual responsibility to maintain Health and Safety values and ensure everyone working on our projects can operate in a safe environment, without the risk of accident or injury.

Quality Assurance

Cilantro Engineering’s Quality Assurance Department is made up of exceptional individuals who ensure the highest quality of install are implemented across Cilantro Engineering projects.

Our Quality Assurance values are:

- Exceed client expectations and guarantee complete satisfaction

- Deliver projects efficiently and promptly

- Ensure Quality Management procedures minimise the risk of defects and aftercare visits

- Adhere to all legal requirements and British standards, manufacturer’s recommendations and codes of practice

- Continually improve the quality performance standards

- Effectively communicate quality matters by involving and consulting with employees

- Consistently review the Quality Policy and implement appropriate improvements accordingly

Our ethos is quality is a habit, not an event. We take seriously our quality procedures so that we deliver our services to the best possible standard.

Environmental

Our vision is to actively reduce and minimise environmental impacts. By expanding our knowledge, adopting sustainable practices and designing in accordance with BREEAM we aim to decrease our carbon footprint across our organisation.

Our environmental commitment:

- Adopt the highest environmental standards in all areas of operation.

- Comply with all environmental legislations, regulations and codes of practice relevant to the construction industry.

- Exceeding and implementing industry best practice measures for sustainability across all projects.

- Meet our duty of care requirements in relation to waste by ensuring safe keeping, transportation and subsequent recovery of disposal waste.

- Work with suppliers to ensure they recognise and reduce the environmental impact of their products and transportation.

- Off-site Prefabrication, to reduce damage to materials and waste.

- Delivery vehicles meet FORS silver registration at a minimum.

- Ensure that vehicles and equipment used are well maintained, clean and are always operated within the legal limits.

- Reduce the effects of noise, dust, disturbance and inconvenience.

- Make efficient use of natural resources by conserving energy and water, minimising waste and recycling.